SHANDONG WOSAI BUILDING MATERIAL CO.,LTD

Car lamp Application domain solutions

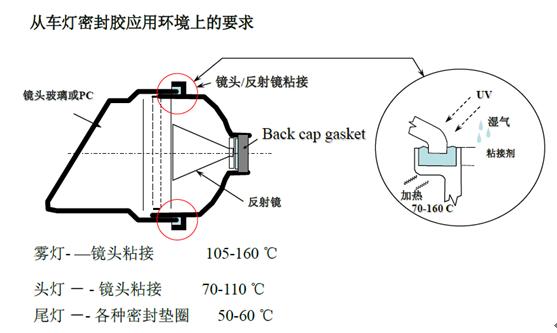

As an essential part in the process of automobile lamp assembly, automobile lamp glue is mainly used to bond the lens and support of automobile lamp. Therefore, the lamp adhesive must ensure that the bonding and sealing performance cannot change under the corresponding high temperature, and will not release organic gas, produce atomization and yellowing; Secondly, the lamp adhesive is exposed to ultraviolet radiation in sunlight, that is, the lamp adhesive is required to have good UV aging resistance; Finally, the lamp adhesive shall withstand the erosion of water vapor and rain in the atmosphere for a long time, without aging and deterioration of sealing performance.

Silicone sealant takes (Si-O) bond as the main chain structure, and the bond energy of Si-O bond (121 kcal / mole) is significantly greater than that of C-C bond (82.6 kcal / mole). Therefore, silicone products have high thermal stability, and the chemical bond of molecules does not break and decompose under high temperature or radiation irradiation. It has certain advantages in the application of automobile lamps.

Pur has the advantages of hot-melt adhesive and single component silica gel as adhesive for lamp. Similar to ordinary hot-melt adhesive, PUR adhesive is heated, melted and coated on the lamp by glue melting machine, cooled and solidified rapidly to achieve high initial bonding strength, and the bonded parts can be moved, assembled and other operations. Then, in the process of product preservation or transportation, PUR glue will continue to react with water in the air to further increase the degree of curing and become a colloid with high strength, temperature resistance and solvent erosion resistance.